Our Factory

Anping County Joylink Wire Mesh Factory is committed to the core concepts of "green production, intelligent manufacturing, and efficient management," aiming to build a modern, standardized wire mesh manufacturing base that ensures product reliability while safeguarding employee health and environmental protection.

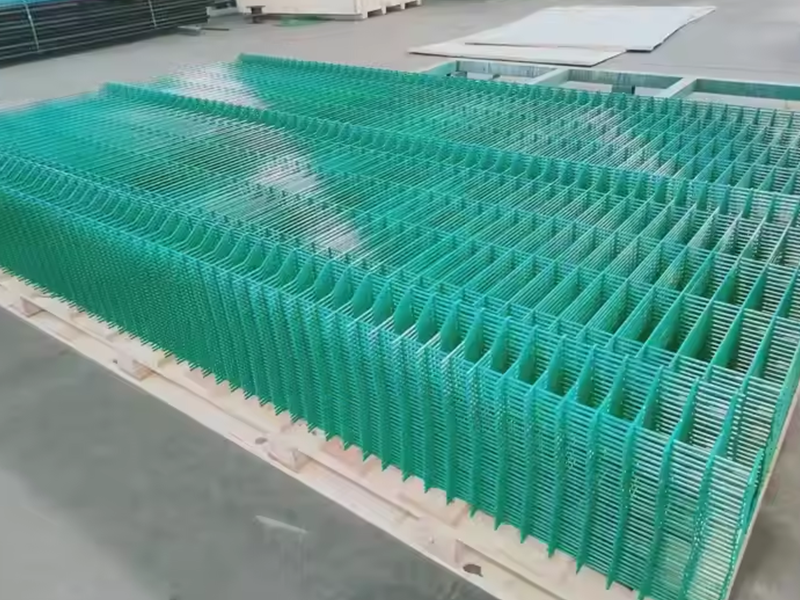

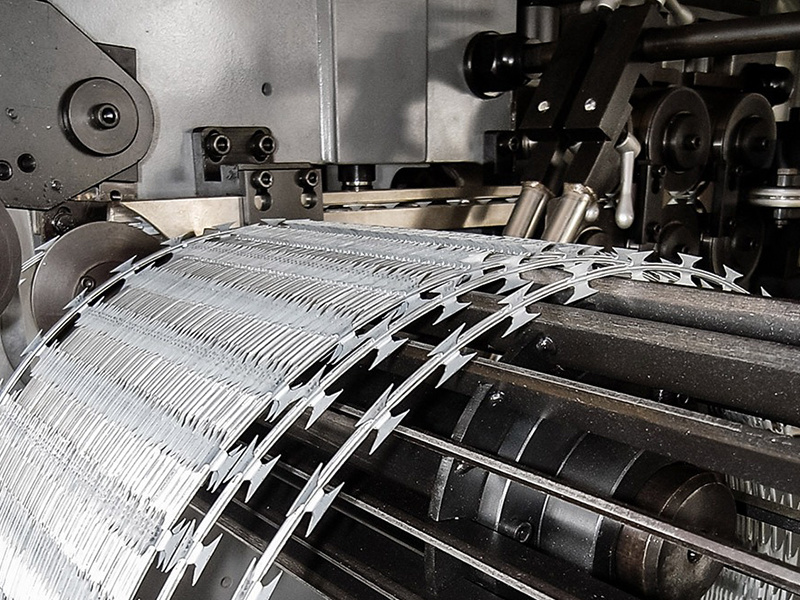

1. Modernized Production Workshops

- Automated Equipment: Advanced CNC weaving machines, high-speed punching machines, laser cutting machines, welding machines, etc., enhance precision and efficiency.

- Functional Zoning: Workshops are divided into raw material, weaving, punching, welding, surface treatment, and quality inspection zones, ensuring an orderly production flow.

- Temperature & Humidity Control: Precision mesh production areas are equipped with climate control systems to maintain product consistency.

2. Environmental Protection and Sustainability

- Exhaust Treatment: High-efficiency dust removal and gas purification systems in welding and electroplating areas comply with national emission standards.

- Wastewater Recycling: On-site industrial wastewater treatment station enables water reuse, reducing resource consumption.

- Noise Control: Low-noise equipment and soundproofing installations in noisy areas protect workers’ health.

3. Strict Quality Control System

- Online Inspection: Smart testing equipment (e.g., optical sorters, tensile testers) is used during key processes to monitor product quality in real time.

- Laboratory Support: An independent quality lab ensures raw materials, semi-finished, and finished products meet national (GB), American (ASTM), and European (EN) standards.

- Traceability Management: An MES (Manufacturing Execution System) tracks production data for each batch, ensuring full product traceability.

4. Safety and Employee Care

- Safe Production: Regular safety training and emergency drills.

- Protective Measures: Employees receive dust masks, goggles, earplugs, and other PPE; high-risk areas have interlock safety systems.

- Comfortable Environment: Workshops are equipped with ventilation systems, rest areas, and drinking water facilities for a pleasant working atmosphere.

5. Digital & Intelligent Management

- Smart Warehousing: Automated vertical warehouses enable intelligent storage and retrieval of raw materials and finished products, improving logistics efficiency.

- Data Monitoring: Real-time monitoring of equipment operation and energy consumption optimizes production scheduling.

- Remote Maintenance: Key equipment supports remote diagnostics and maintenance to minimize downtime and ensure production continuity.