- 产品描述

-

Product Introduction

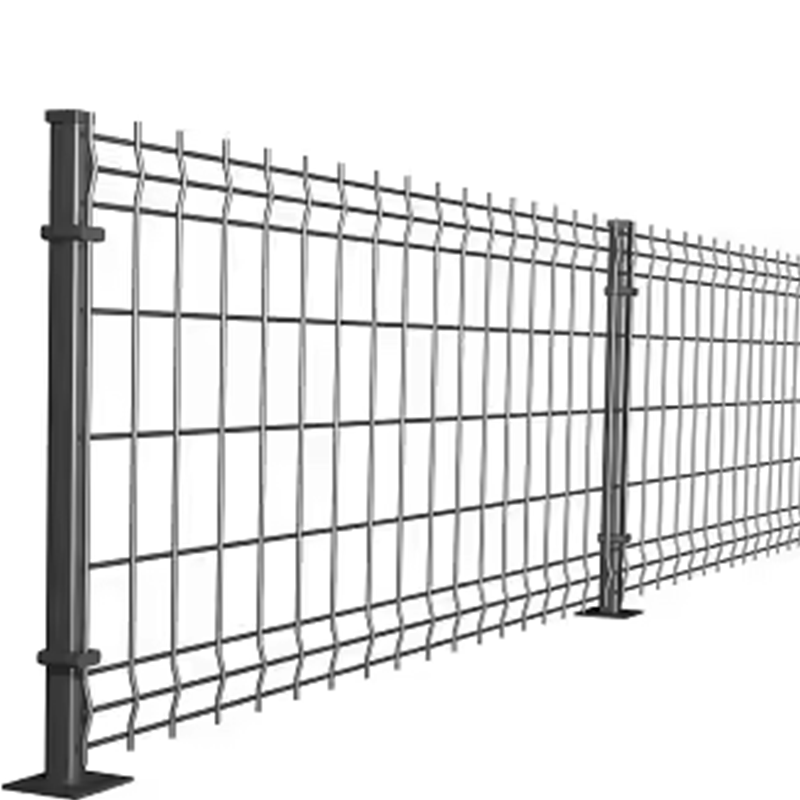

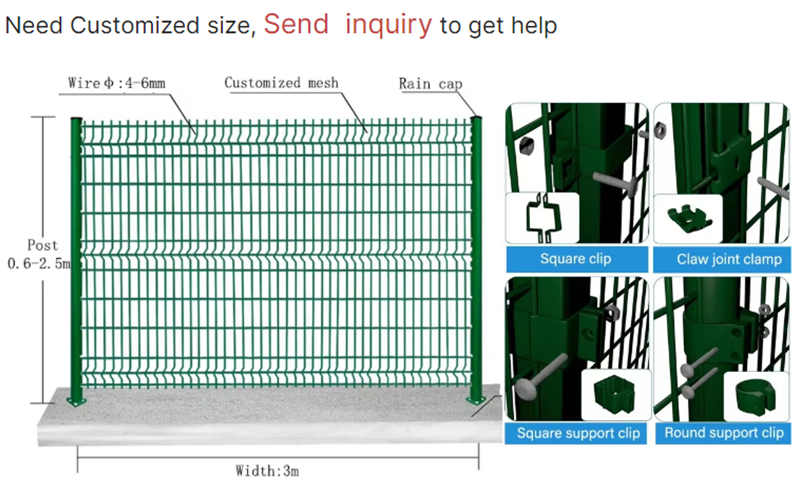

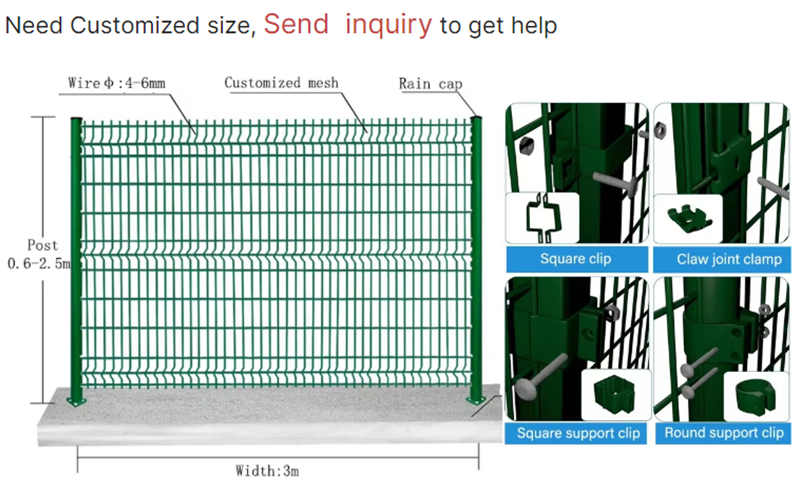

3D Curved Fence is made by welded wire mesh panels with curves and fence post.The series of protective mesh are simple in structure, beautiful in practicality, easy in transportation,convenient in installation and suitable in topography. 3D Curved Fence is pretty light yet durable, The surface treatment of Welded wire mesh fence includes: hot-dipped galvanized, PVC coated, powder coated.

Peach post:No screws or bolts are needed between the mesh and the columns. The installation is convenient and the appearance is beautiful.

Round pipe post : The bent mesh and the square column are connected through different connection methods.

Specifications

Wire opening:55 mm x 100 mm, 50 mm x 200 mm, 55 mm x 200mm

Panel height:1.5-2.5m

Panel width : 2、2.5、3mPost type : Round Post : 48x1.5/2.0mm 60x1.5/2.0mm

Square Post(SHS) : 50X50x1.5/2.0mm 60x60x1.5/2.0mm 80x80x1.5/2.0mm

Rectangular Post(RHS) : 40x60x1.5/2.0mm 40x80x1.5/2.0mm

60x80x1.5/2.0mm 80x100x1.5/2.0mmSurface Treatment

hot dipped galvanized,

galvanized +powder coated,

galvanized +PVC coating

Color

RAL 6005 green,

RAL 7016 gray,

All RAL color can be customizedApplications

Isolation and protection for villa complexes, municipal construction, hotels, airports, prisons and other tourist attractions

Production Process

1.Preparation of raw materials

The production of curved fence requires the preparation of the necessary raw materials, mainly including steel wires, steel pipes, welding materials, etc. The steel wire is the main material of the guardrail net, usually using high-quality low-carbon steel wire or stainless steel wire. The steel pipes are used to make the upright columns of the curved fence, usually using galvanized steel pipes or aluminum alloy pipes.

2.Steel wire drawing

Pull the steel wire to make it more uniform and fine

3.Cutting

Cut the drawn steel wire. Make the cuts according to the required length.。4.Bending

Cut the steel wire and then bend it to form the desired shape, such as square or circular.

5.Welding

The fabricated steel wires are to be welded. Welding is a crucial step in the production of the fence net, requiring the use of professional welding equipment and welding materials. The steel wires are welded onto the posts to form a grid-like structure. During the welding process, attention should be paid to the uniformity and firmness of the weld points to ensure the stability and safety of the fence net.

6.Surface treatment

The welded fence net is subjected to surface treatment. Generally, hot-dip galvanizing or powder coating methods are used for surface treatment to enhance the corrosion resistance and appearance of the fence net. Powder coating involves spraying a layer of plastic powder onto the fence net, which then undergoes high-temperature baking to form a sturdy plastic film.

7.Installation

As needed, fix the guardrail net on the ground or the wall using screws or welding, etc. During the installation process, pay attention to the flatness and stability of the guardrail net to ensure that it can perform the functions of isolation and protection.

3D Curved Fence

3D Curved Fence is made by welded wire mesh panels with curves and fence post.The series of protective mesh are simple in structure, beautiful in practicality, easy in transportation,convenient in installation and suitable in topography. 3D Curved Fence is pretty light yet durable, The surface treatment of Welded wire mesh fence includes: hot-dipped galvanized, PVC coated, powder coated.

Share to

- 产品描述

-

Product Introduction

3D Curved Fence is made by welded wire mesh panels with curves and fence post.The series of protective mesh are simple in structure, beautiful in practicality, easy in transportation,convenient in installation and suitable in topography. 3D Curved Fence is pretty light yet durable, The surface treatment of Welded wire mesh fence includes: hot-dipped galvanized, PVC coated, powder coated.

Peach post:No screws or bolts are needed between the mesh and the columns. The installation is convenient and the appearance is beautiful.

Round pipe post : The bent mesh and the square column are connected through different connection methods.

Specifications

Wire opening:55 mm x 100 mm, 50 mm x 200 mm, 55 mm x 200mm

Panel height:1.5-2.5m

Panel width : 2、2.5、3mPost type : Round Post : 48x1.5/2.0mm 60x1.5/2.0mm

Square Post(SHS) : 50X50x1.5/2.0mm 60x60x1.5/2.0mm 80x80x1.5/2.0mm

Rectangular Post(RHS) : 40x60x1.5/2.0mm 40x80x1.5/2.0mm

60x80x1.5/2.0mm 80x100x1.5/2.0mmSurface Treatment

hot dipped galvanized,

galvanized +powder coated,

galvanized +PVC coating

Color

RAL 6005 green,

RAL 7016 gray,

All RAL color can be customizedApplications

Isolation and protection for villa complexes, municipal construction, hotels, airports, prisons and other tourist attractions

Production Process

1.Preparation of raw materials

The production of curved fence requires the preparation of the necessary raw materials, mainly including steel wires, steel pipes, welding materials, etc. The steel wire is the main material of the guardrail net, usually using high-quality low-carbon steel wire or stainless steel wire. The steel pipes are used to make the upright columns of the curved fence, usually using galvanized steel pipes or aluminum alloy pipes.

2.Steel wire drawing

Pull the steel wire to make it more uniform and fine

3.Cutting

Cut the drawn steel wire. Make the cuts according to the required length.。4.Bending

Cut the steel wire and then bend it to form the desired shape, such as square or circular.

5.Welding

The fabricated steel wires are to be welded. Welding is a crucial step in the production of the fence net, requiring the use of professional welding equipment and welding materials. The steel wires are welded onto the posts to form a grid-like structure. During the welding process, attention should be paid to the uniformity and firmness of the weld points to ensure the stability and safety of the fence net.

6.Surface treatment

The welded fence net is subjected to surface treatment. Generally, hot-dip galvanizing or powder coating methods are used for surface treatment to enhance the corrosion resistance and appearance of the fence net. Powder coating involves spraying a layer of plastic powder onto the fence net, which then undergoes high-temperature baking to form a sturdy plastic film.

7.Installation

As needed, fix the guardrail net on the ground or the wall using screws or welding, etc. During the installation process, pay attention to the flatness and stability of the guardrail net to ensure that it can perform the functions of isolation and protection.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.

Related Products

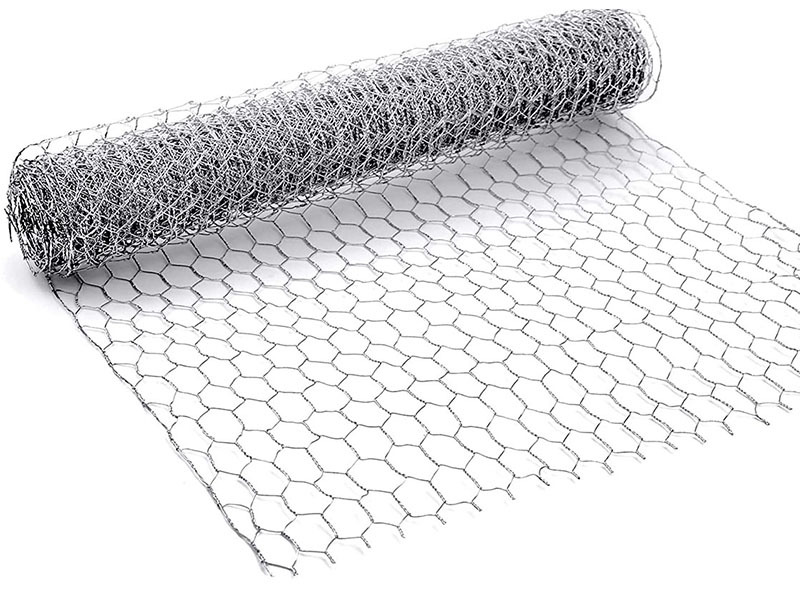

Hexagonal mesh is a net-like material woven or welded from metal wire, named for its hexagonal (honeycomb) mesh structure. It is also known as hexagonal wire mesh, chicken wire, hex mesh, or gabion mesh.

3D Curved Fence is made by welded wire mesh panels with curves and fence post.The series of protective mesh are simple in structure, beautiful in practicality, easy in transportation,convenient in installation and suitable in topography. 3D Curved Fence is pretty light yet durable, The surface treatment of Welded wire mesh fence includes: hot-dipped galvanized, PVC coated, powder coated.

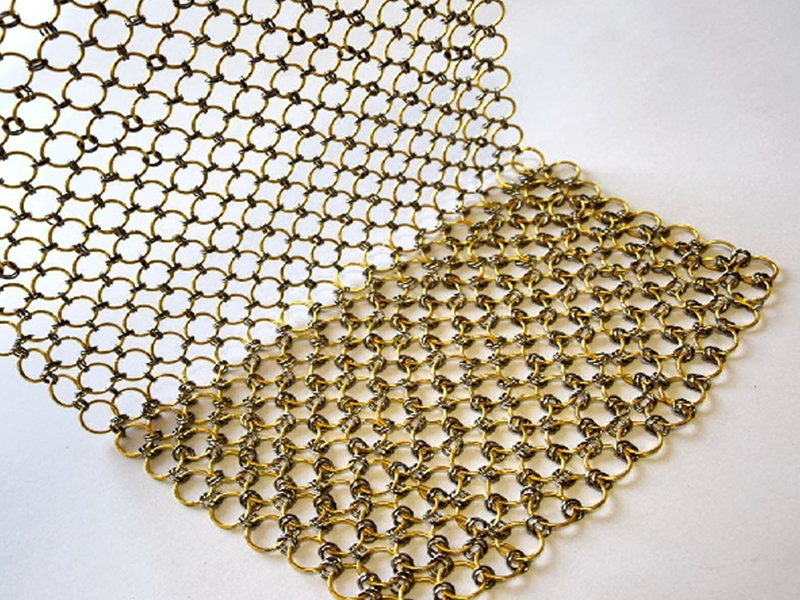

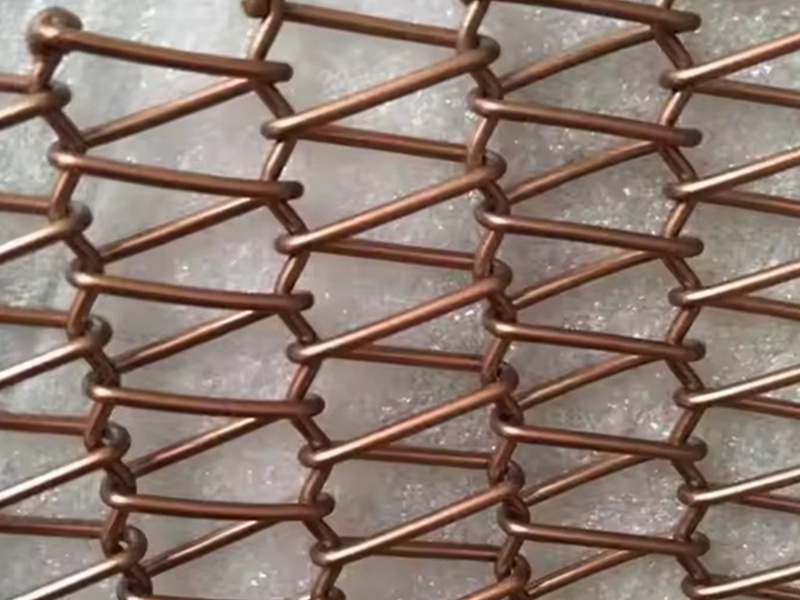

decorative metal curtain is a stylish and functional architectural element made from metal mesh, chain links, or interlocked rings. It is used in both residential and commercial interiors and exteriors for aesthetic appeal and practical purposes.

decorative metal curtain is a stylish and functional architectural element made from metal mesh, chain links, or interlocked rings. It is used in both residential and commercial interiors and exteriors for aesthetic appeal and practical purposes.