- 产品描述

-

Product Introduction

Woven Gabion Basket are structures made of wire or polymer mesh that hold the stones in place. Wire cages are formed by weaving wire or welding components together. These structures can be electroplated. The woven wire boxes can be additionally coated with PVC. Using resistant and hard stones as fill material, they will not break down quickly due to erosion in the stone boxes or geocell sedimentation systems. They are widely used in landscape engineering projects such as road embankments, dam banks, and reforestation of steep slopes on mountains.

Specifications

Mesh size: 60x80mm,80x100mm,100x120mm,120x150mm and so on.

Wire diameter: 2.0-4.0mm

Mesh Wire: 2.0mm,2.4mm,2.7mm,3.2mm,3.4mm,4mm

Selvege Wire: 2.4mm,2.7mm,3mm,3.4mm,4mm

Lacing Wire: 2.0mm, 2.2mm, 2.5mmSurface Treatment

galvanized wire, galfan wire and PVC coated wire

Gabion Size

1x1x0.5m, 2x1x1m, 3x1x1m, 4x1x1m, 2x1x0.3m

Applications

Retaining walls

Temporary bridge abutments

Beach reinforcement

River bank revetment

Landscaped boundaries

Stone flowerpot

Courtyard security wall

Production Process

1.Raw material selection (wire rod):

We have a reliable supply channel, which can ensure the quality of the raw materials and reduce costs, providing more benefits to the customers.2.Cold drawing, galvanizing and plastic coating:

These are essential steps that can make the gabion net more durable, resistant to corrosion and have a longer service life.

3.Machine weaving:

We have 12 machines, which can operate simultaneously. Each machine can produce 5,000 square meters of wire mesh per day, with a very fast speed! It is the continuous innovation of the weaving machines that has greatly accelerated the weaving speed and made the mesh net more regular, symmetrical, and enhanced its aesthetic appeal.4.Cutting and assembly:

Different from manual cutting in the past, now we use a CNC cutting machine. This machine can cut according to the customer's requirements, which is 30% faster than manual cutting. At the same time, it has the advantages of a flat mesh surface and neat breaks.

5.Product inspection:

The product inspection equipment is also very different from before. It can detect product problems more efficiently and thoroughly.6.Packaging and transportation:

The compression and packaging method can significantly reduce the volume of wire mesh packaging. It can reduce the packaging volume by 50% quickly, making it easier to transport and saving transportation costs, thus further saving money.

Woven Gabion Basket

Woven Gabion Basket are structures made of wire or polymer mesh that hold the stones in place. Wire cages are formed by weaving wire or welding components together. These structures can be electroplated. The woven wire boxes can be additionally coated with PVC. Using resistant and hard stones as fill material, they will not break down quickly due to erosion in the stone boxes or geocell sedimentation systems. They are widely used in landscape engineering projects such as road embankments, dam banks, and reforestation of steep slopes on mountains.

Share to

- 产品描述

-

Product Introduction

Woven Gabion Basket are structures made of wire or polymer mesh that hold the stones in place. Wire cages are formed by weaving wire or welding components together. These structures can be electroplated. The woven wire boxes can be additionally coated with PVC. Using resistant and hard stones as fill material, they will not break down quickly due to erosion in the stone boxes or geocell sedimentation systems. They are widely used in landscape engineering projects such as road embankments, dam banks, and reforestation of steep slopes on mountains.

Specifications

Mesh size: 60x80mm,80x100mm,100x120mm,120x150mm and so on.

Wire diameter: 2.0-4.0mm

Mesh Wire: 2.0mm,2.4mm,2.7mm,3.2mm,3.4mm,4mm

Selvege Wire: 2.4mm,2.7mm,3mm,3.4mm,4mm

Lacing Wire: 2.0mm, 2.2mm, 2.5mmSurface Treatment

galvanized wire, galfan wire and PVC coated wire

Gabion Size

1x1x0.5m, 2x1x1m, 3x1x1m, 4x1x1m, 2x1x0.3m

Applications

Retaining walls

Temporary bridge abutments

Beach reinforcement

River bank revetment

Landscaped boundaries

Stone flowerpot

Courtyard security wall

Production Process

1.Raw material selection (wire rod):

We have a reliable supply channel, which can ensure the quality of the raw materials and reduce costs, providing more benefits to the customers.2.Cold drawing, galvanizing and plastic coating:

These are essential steps that can make the gabion net more durable, resistant to corrosion and have a longer service life.

3.Machine weaving:

We have 12 machines, which can operate simultaneously. Each machine can produce 5,000 square meters of wire mesh per day, with a very fast speed! It is the continuous innovation of the weaving machines that has greatly accelerated the weaving speed and made the mesh net more regular, symmetrical, and enhanced its aesthetic appeal.4.Cutting and assembly:

Different from manual cutting in the past, now we use a CNC cutting machine. This machine can cut according to the customer's requirements, which is 30% faster than manual cutting. At the same time, it has the advantages of a flat mesh surface and neat breaks.

5.Product inspection:

The product inspection equipment is also very different from before. It can detect product problems more efficiently and thoroughly.6.Packaging and transportation:

The compression and packaging method can significantly reduce the volume of wire mesh packaging. It can reduce the packaging volume by 50% quickly, making it easier to transport and saving transportation costs, thus further saving money.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.

Related Products

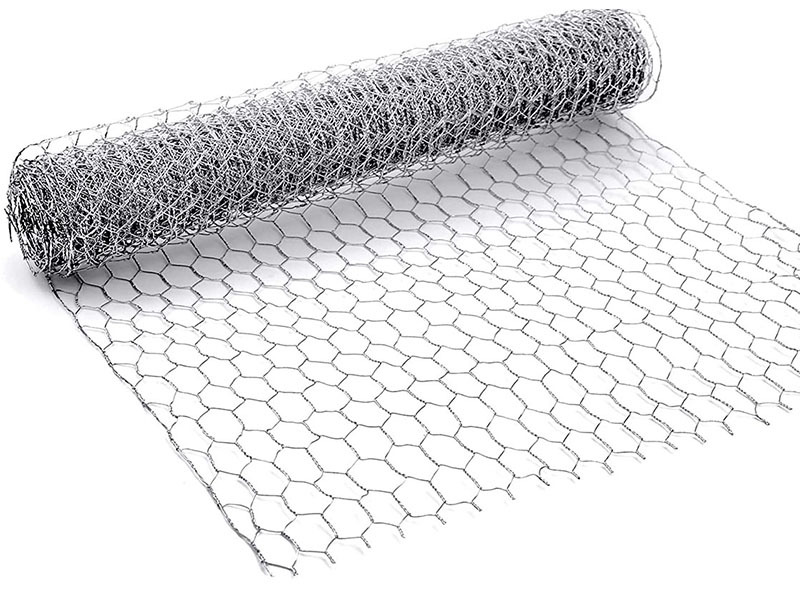

Hexagonal mesh is a net-like material woven or welded from metal wire, named for its hexagonal (honeycomb) mesh structure. It is also known as hexagonal wire mesh, chicken wire, hex mesh, or gabion mesh.

3D Curved Fence is made by welded wire mesh panels with curves and fence post.The series of protective mesh are simple in structure, beautiful in practicality, easy in transportation,convenient in installation and suitable in topography. 3D Curved Fence is pretty light yet durable, The surface treatment of Welded wire mesh fence includes: hot-dipped galvanized, PVC coated, powder coated.

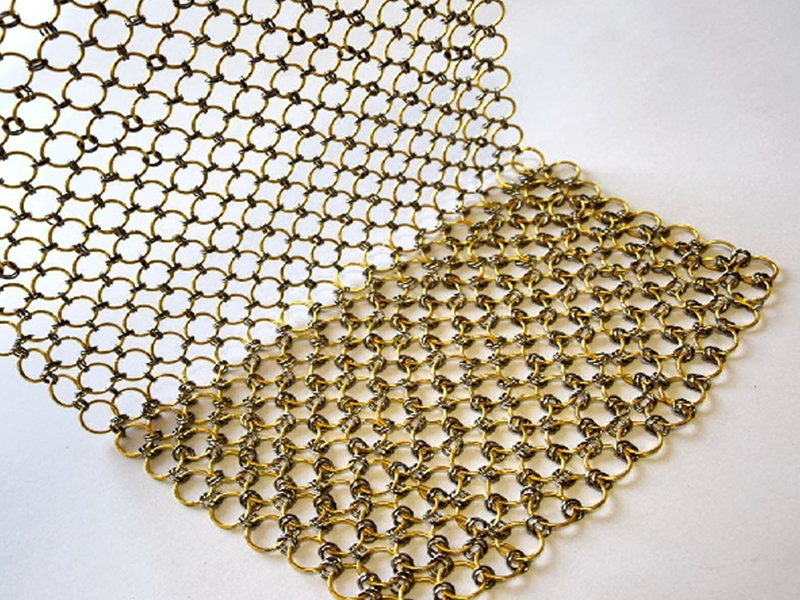

decorative metal curtain is a stylish and functional architectural element made from metal mesh, chain links, or interlocked rings. It is used in both residential and commercial interiors and exteriors for aesthetic appeal and practical purposes.

decorative metal curtain is a stylish and functional architectural element made from metal mesh, chain links, or interlocked rings. It is used in both residential and commercial interiors and exteriors for aesthetic appeal and practical purposes.