- 产品描述

-

Stainless steel belt for biscuit conveyor machines adopted hard SS304,SS316 and spring wire,many advantages about the wire belt like good open area,smooth surface and light weight,flat flex wire belt widely used in food processing include biscuit,chocolate,enrober,cooling,drying,bread baking.

The wire belts are custom made by requirements and wire diameter from 0.8 mm to 3.0 mm.We design and make the full mesh belt conveyor for food processing,electronic products.The Ladder conveyor belt has a single-layer structure, is lighter, and is driven by a sprocket. The large opening area (opening 70-85%) makes the mesh belt very breathable. The mesh belt is made of stainless steel high-elasticity and flexible wire, which can be used for linear conveyors or curved conveyors.

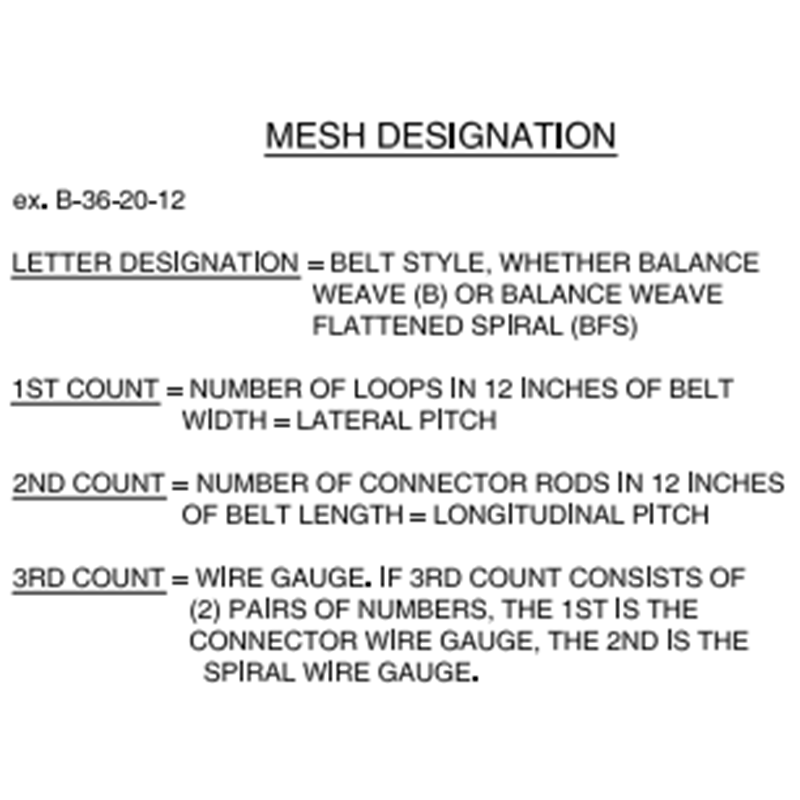

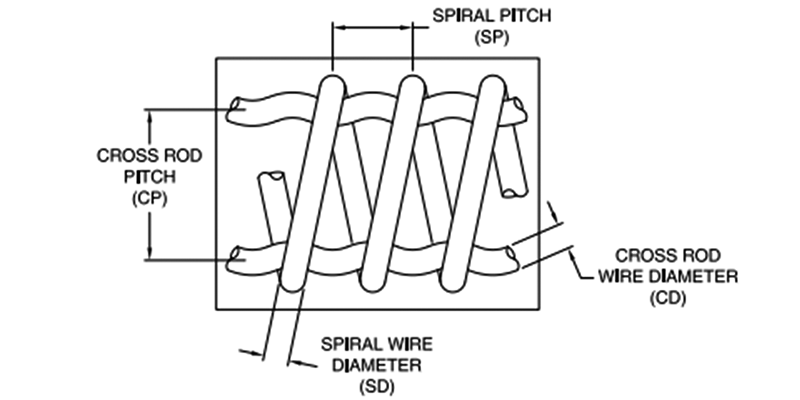

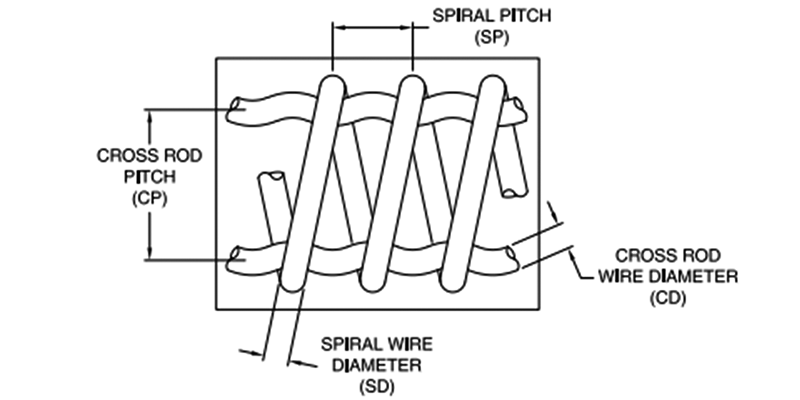

Balanced Weave

Manufactured using left&right hand spiral connected with a crimped connecting rod to creat a balanced weave that is straight tracking. This weave is designated with the letter “B”.

Balanced weave is the most common weave used in general friction driven applications, positive driven mesh, and chain driven applications. Often used for architectural mesh and safety curtains. Available any material.

B-72-24-16

B=balance weave designation

72=72loops of wire per foot width

24=24spirals connected in a foot of length

16=gauge of wire(.062”diameter)

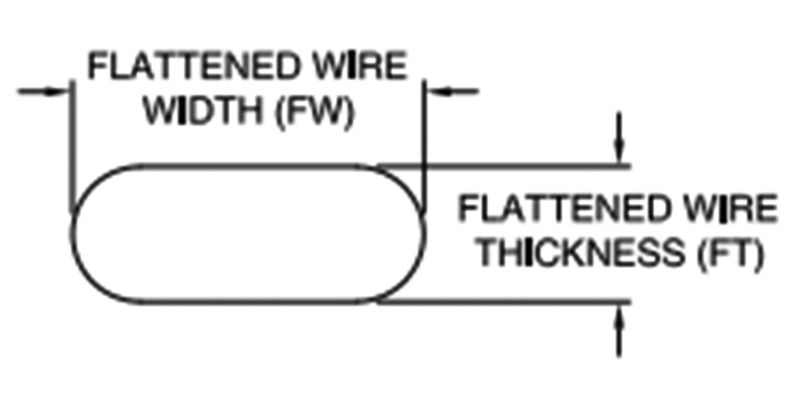

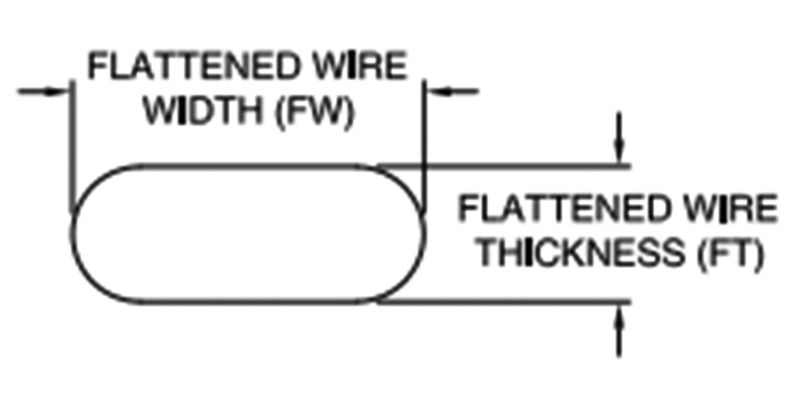

BELT SPECIFICATION BELT WIDTH BELT LENGTH BELT MATERIAL EDGE FINISH BELT STYLE B or BFS SP SD CP CD *FW *FT

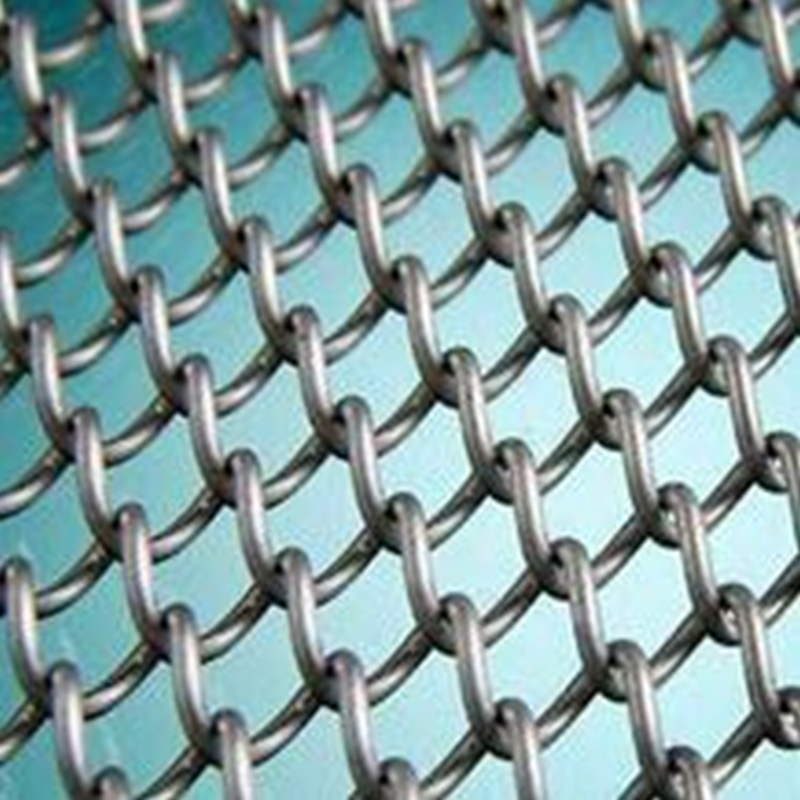

Double Balanced Weave

A modified variation of balance weave, using two inter-woven spirals. Two 12 pitch spirals are woven together to form a 24 pitch belt. Awailable in any material.

Most commonly used in elevated temperature applications for Sintering, Brazing and Annealing.

DB-24-10-6-8

DB=double balance

24=24 loops of wire per foot width

10=10spirals connected in a foot of length

6=6 gauge connecting pin(.192” diameter)

8=8 gauge spiral wire(.162” diameter)

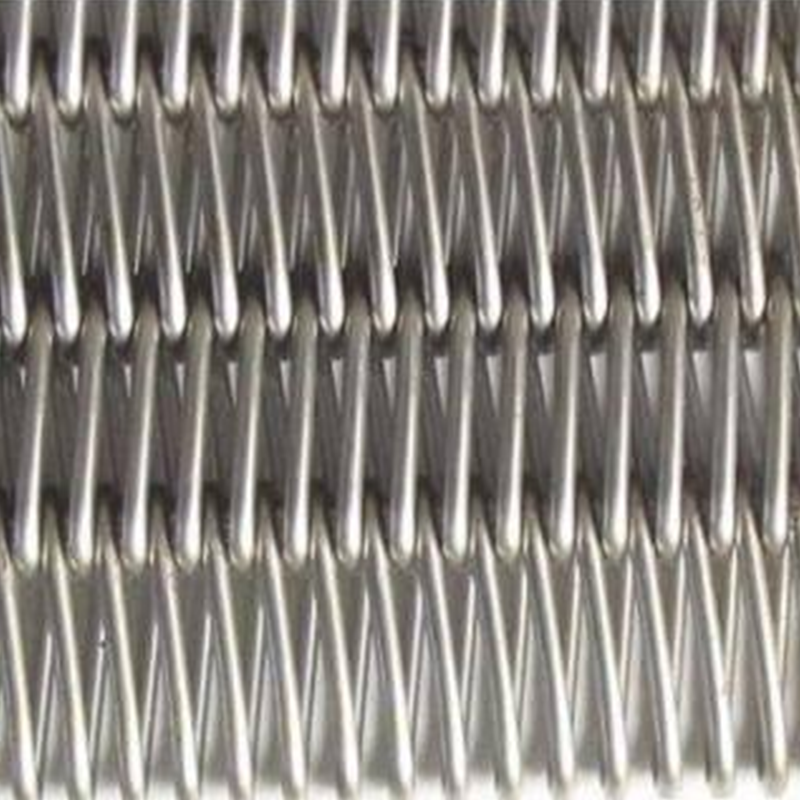

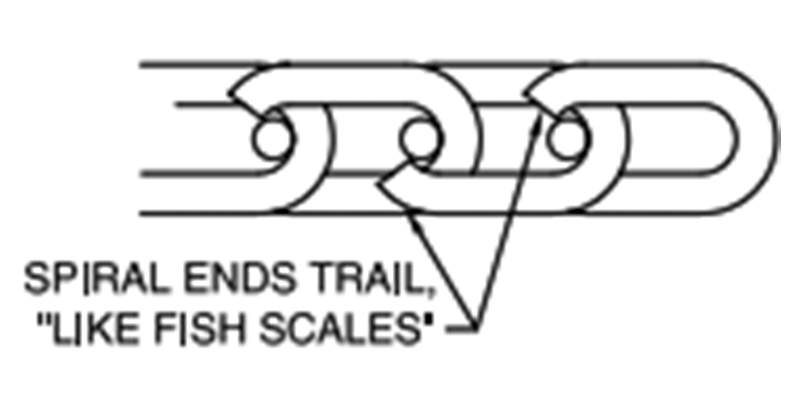

Conventional Weave

Also referred to as chain link mesh since it is woven in the same manner as chain link fencing. All spirals are of the same direction and are woven together without the use of the connecting rods.

Generally used in chain driven applications where exceptional drainage of open area are required. Awailable in any material.

CLK-24-24-16 or 1/2”x16 gauge conventional weave

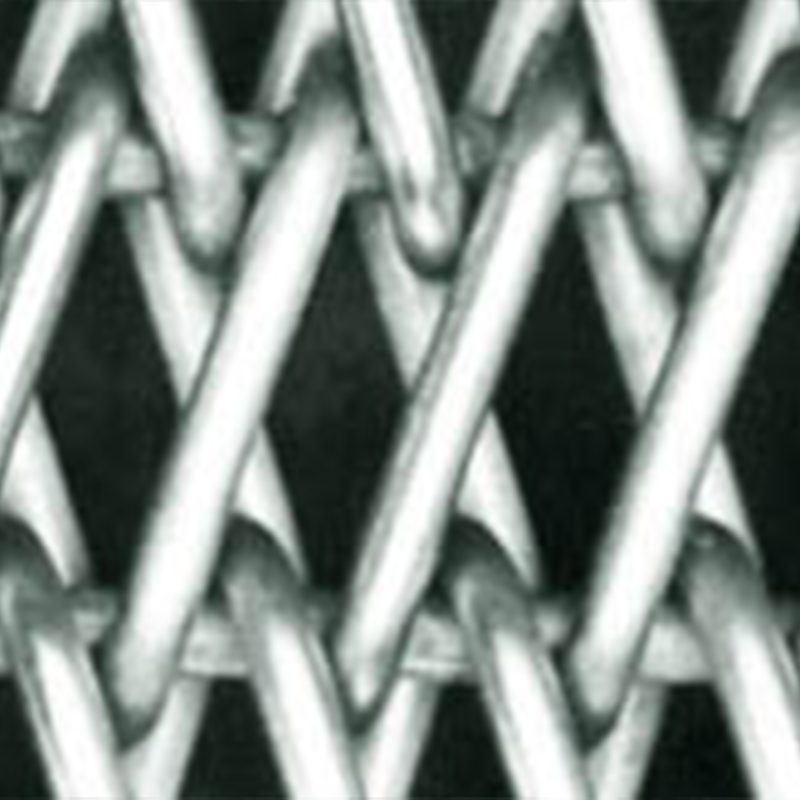

Compound Balanced Weave (Cordweave)

A variation of the balanced weave, consisting of alternating left&right hand spirals compressed to create a very tight weave with a flat surface. Generally assembled with a straight connecting rod, but is available in limited specifications with a crimped connecting rod.

Common mesh used for small fasteners, catalyst and baking bands. Also used as furnace curtains. Available in any material.

CB3-30-72-14

CB=compound balance

3=3 cross rods per spiral

30=30loops per foot width per spiral

72=72 spirals per foot length

14=14gauge wire(.080” dia.)

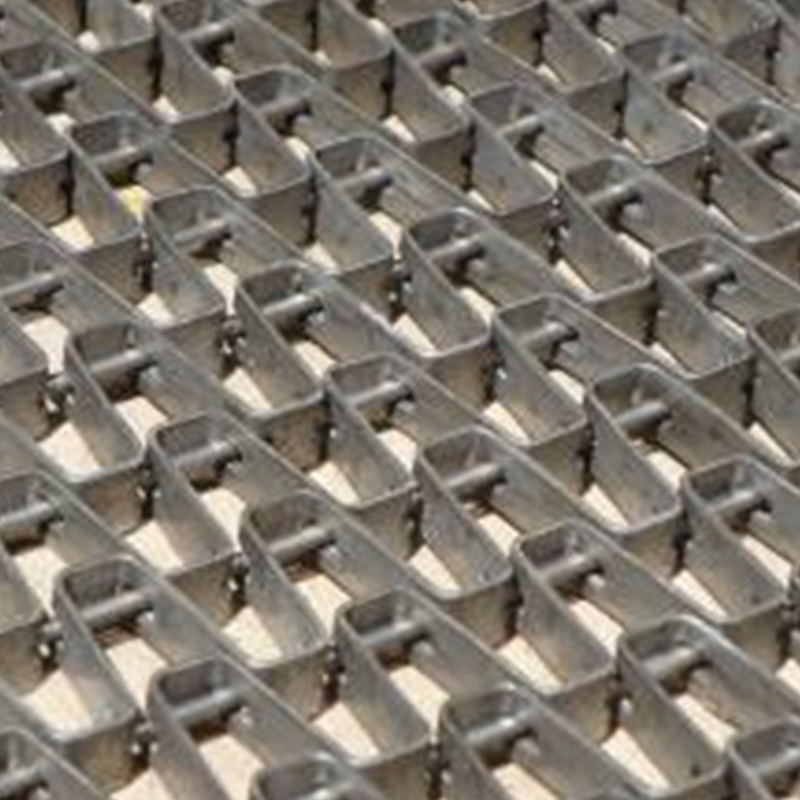

Flat Wire Belting

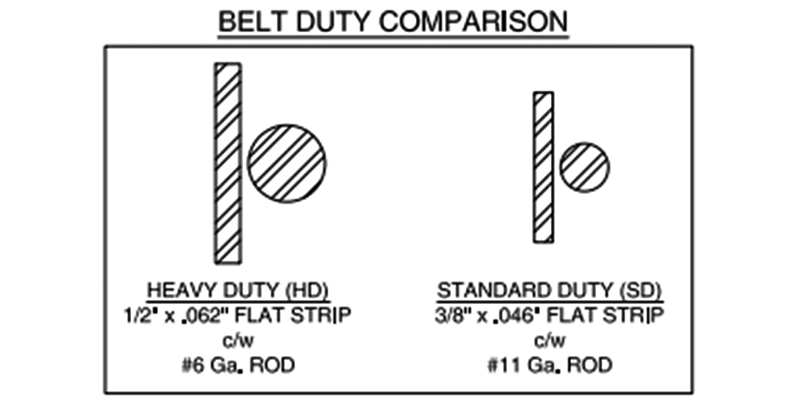

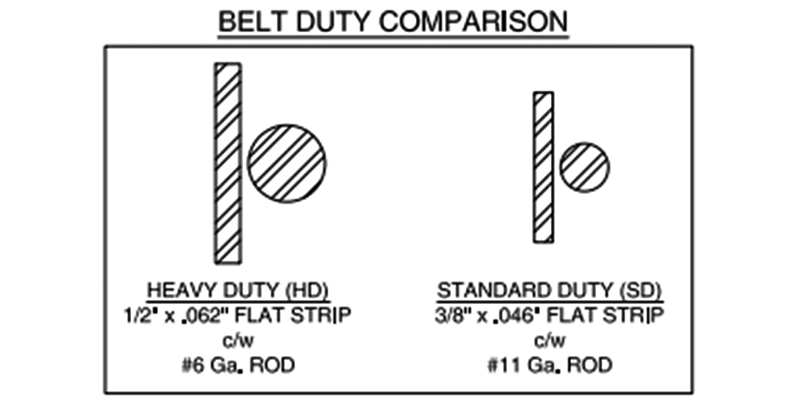

Cost effective open design belting using flat strip to form spirals in a rectangular opening joined with straight pins. Available in standard duty(3/8” thick) and heavy duty(1/2” thick) series. Available meshes are: standard duyt 1x1, 1/2x1, 1/2x1 modified, 1x1 radius, 1/2x1 radius.

Heavy duty 1x1, 1/2x1, 1/2x1 modified, 1x1radius, 1/2x1radius.

Flat wire belting is available in galvanized, high carbon and stainless steel. A complete line of sprockets, shafts, flights and attachments are available.

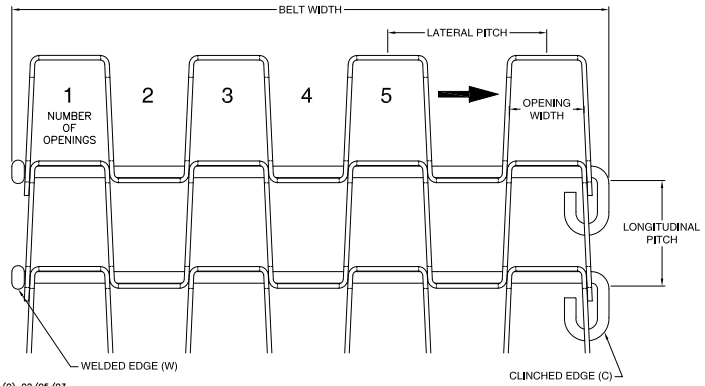

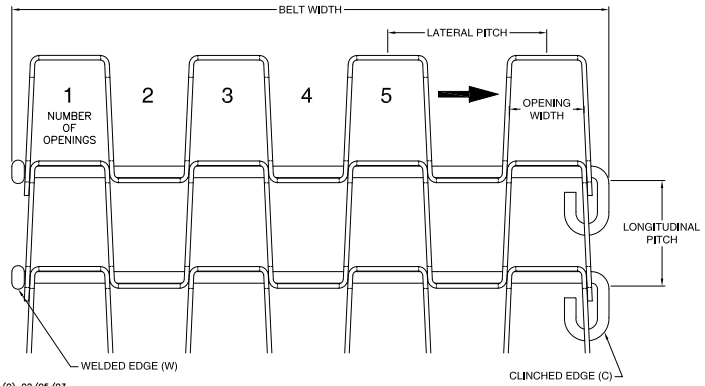

BELT SPECIFICATION BELT WIDTH NO.OF OPENINGS BELT LENGTH BELT MATERIAL EDGE FINISH BELT DUTY LATERAL PITCH LONGITUDINAL PITCH OPENING WIDTH

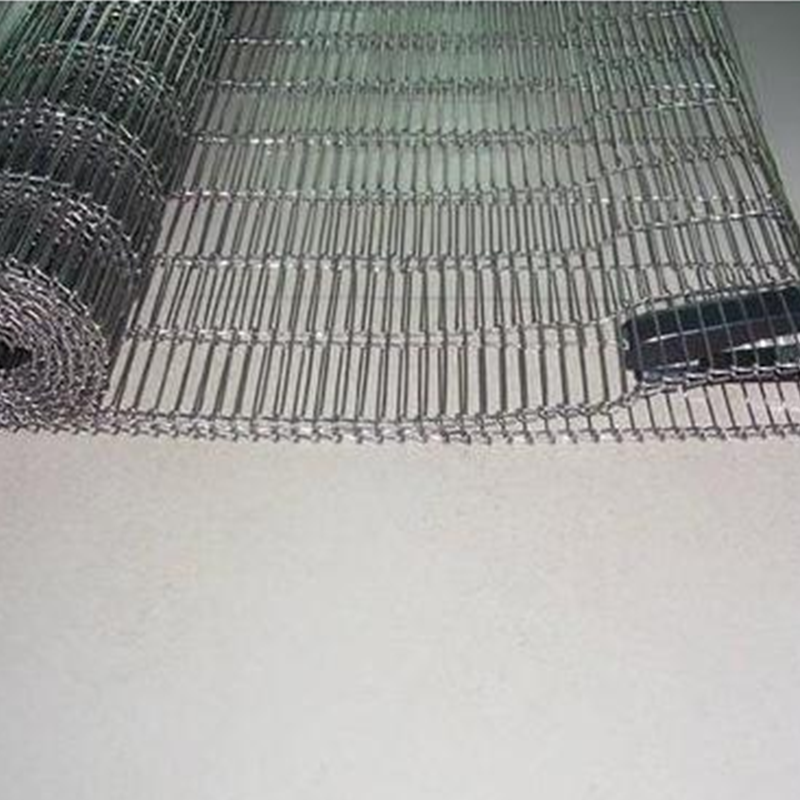

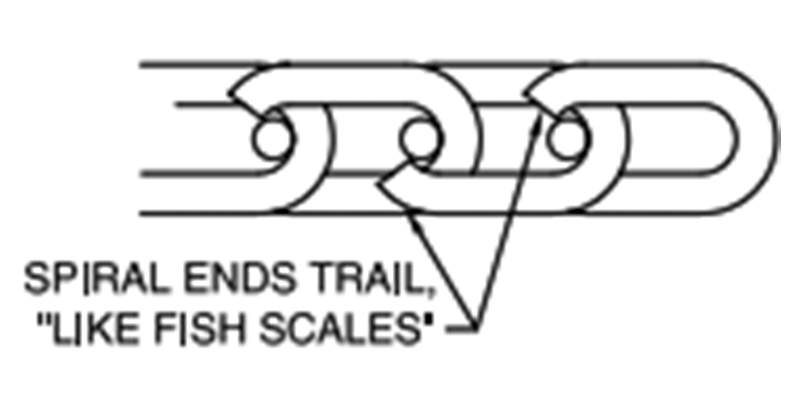

Flat-Flexing Belting

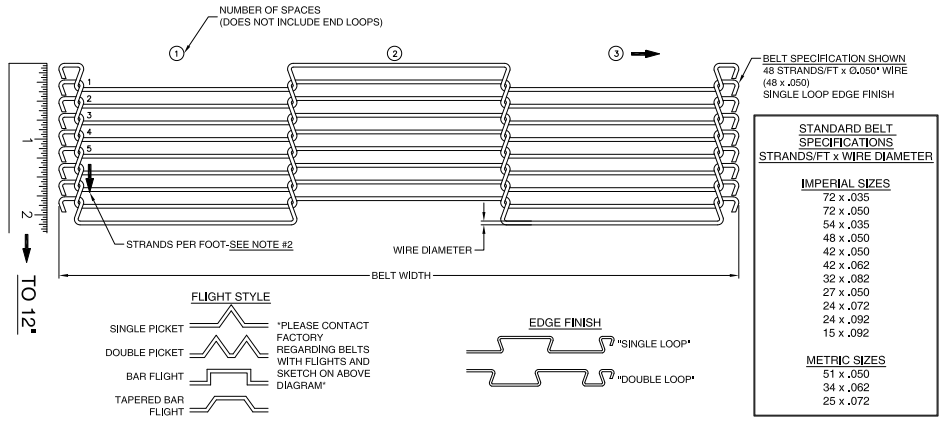

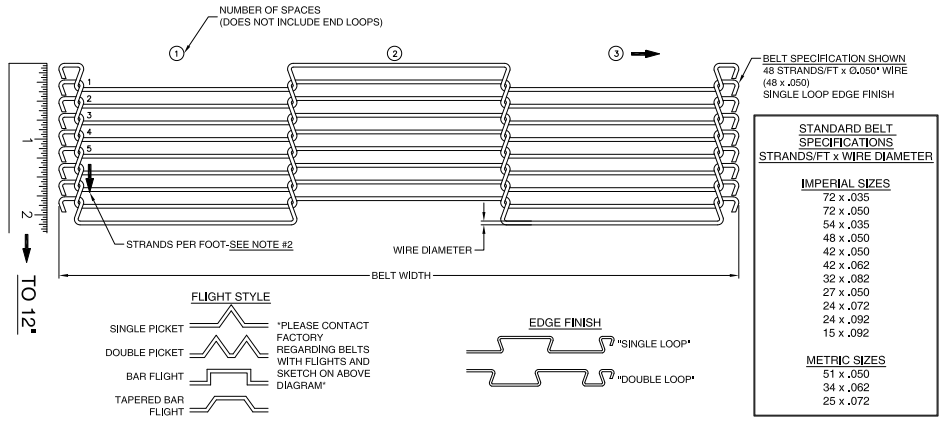

Light weight&open construction makes this belt popular in baking and food processing. Positive driven belting manufactured from stainless steel and music wire. This belt is manufactured in the following standard meshes:

72x.035”, 48x.050”, 32x.082”, 24x.092”,

72x.050”, 42x.050”, 27x.050”, 15x.092”

54x.035”, 42x.062”x 24x.072”

Also available in metric pitch. Complete line of sprockets, blanks, shafts, turn belts and complete conveyor units.

BELT SPECIFICATION BELT NUMBER BELT LENGTH STRANDS/FT WIRE DIAMETER BELT WIDTH #OF SPACES EDGE FINISH MATERIAL Chain Drive Belting

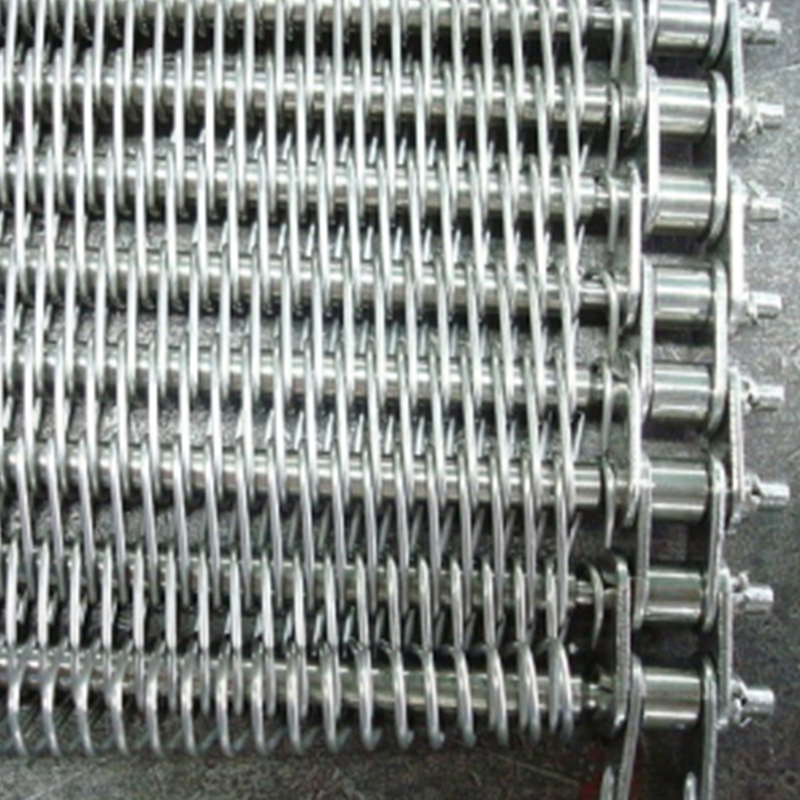

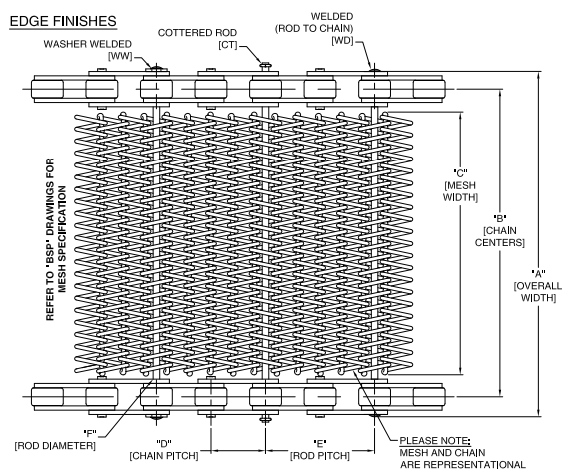

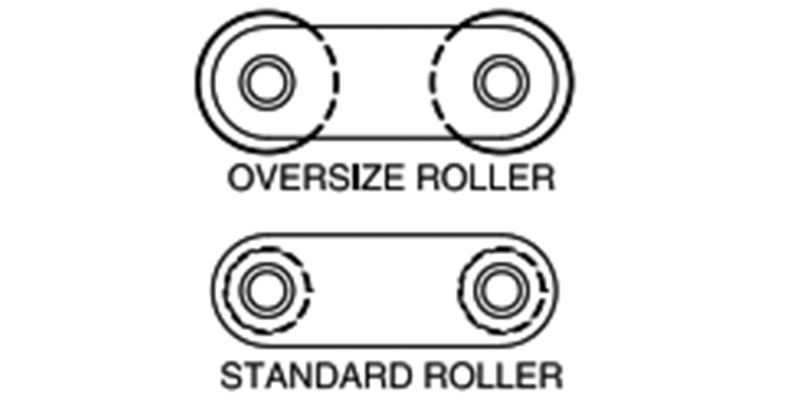

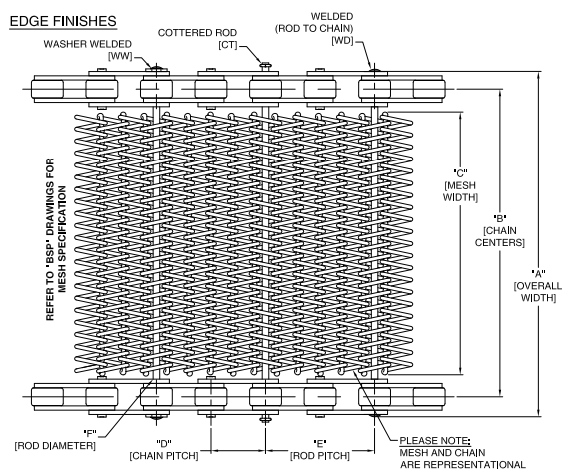

Mesh belting with chain attached to each edge for positive drive. The chain can be attached by rods that pass through the mesh or with channel/bar supports that are bolted/welded to the chain. The construction method used in based on the capacity required and the mesh will be determined by the smallest part size. Most common meshes are balanced weave mesh woven to accommodate the support spacing.

Common applications are ovens, quench tanks, wahers, fryers, greezers and any application that requires posivive drive to eliminate any potential tracking problems.

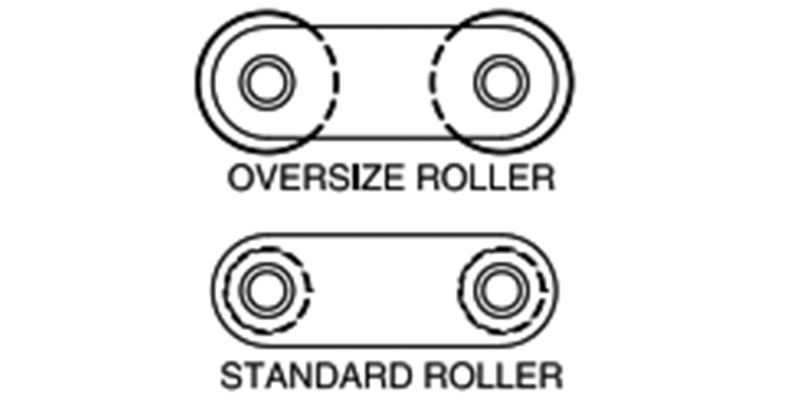

BELT SPECIFICATION VARIABLES DATA MATERIAL ''A'' ''B'' ''C'' ''D'' ''E'' ''F'' CHAIN NUMBER ROLER SIZE STD or OVR EDGE FINISH WW CT WD MESH SPEC. NOTES: (IE. SIDE PLATES,FLIGHTS,OVERSIZED NODS ETC.) PLEASE CIRCLE CRITICAL DIMENSION ''A'' ''B'' ''C''

Conveyor Belt

Share to

- 产品描述

-

Stainless steel belt for biscuit conveyor machines adopted hard SS304,SS316 and spring wire,many advantages about the wire belt like good open area,smooth surface and light weight,flat flex wire belt widely used in food processing include biscuit,chocolate,enrober,cooling,drying,bread baking.

The wire belts are custom made by requirements and wire diameter from 0.8 mm to 3.0 mm.We design and make the full mesh belt conveyor for food processing,electronic products.The Ladder conveyor belt has a single-layer structure, is lighter, and is driven by a sprocket. The large opening area (opening 70-85%) makes the mesh belt very breathable. The mesh belt is made of stainless steel high-elasticity and flexible wire, which can be used for linear conveyors or curved conveyors.

Balanced Weave

Manufactured using left&right hand spiral connected with a crimped connecting rod to creat a balanced weave that is straight tracking. This weave is designated with the letter “B”.

Balanced weave is the most common weave used in general friction driven applications, positive driven mesh, and chain driven applications. Often used for architectural mesh and safety curtains. Available any material.

B-72-24-16

B=balance weave designation

72=72loops of wire per foot width

24=24spirals connected in a foot of length

16=gauge of wire(.062”diameter)

BELT SPECIFICATION BELT WIDTH BELT LENGTH BELT MATERIAL EDGE FINISH BELT STYLE B or BFS SP SD CP CD *FW *FT

Double Balanced Weave

A modified variation of balance weave, using two inter-woven spirals. Two 12 pitch spirals are woven together to form a 24 pitch belt. Awailable in any material.

Most commonly used in elevated temperature applications for Sintering, Brazing and Annealing.

DB-24-10-6-8

DB=double balance

24=24 loops of wire per foot width

10=10spirals connected in a foot of length

6=6 gauge connecting pin(.192” diameter)

8=8 gauge spiral wire(.162” diameter)

Conventional Weave

Also referred to as chain link mesh since it is woven in the same manner as chain link fencing. All spirals are of the same direction and are woven together without the use of the connecting rods.

Generally used in chain driven applications where exceptional drainage of open area are required. Awailable in any material.

CLK-24-24-16 or 1/2”x16 gauge conventional weave

Compound Balanced Weave (Cordweave)

A variation of the balanced weave, consisting of alternating left&right hand spirals compressed to create a very tight weave with a flat surface. Generally assembled with a straight connecting rod, but is available in limited specifications with a crimped connecting rod.

Common mesh used for small fasteners, catalyst and baking bands. Also used as furnace curtains. Available in any material.

CB3-30-72-14

CB=compound balance

3=3 cross rods per spiral

30=30loops per foot width per spiral

72=72 spirals per foot length

14=14gauge wire(.080” dia.)

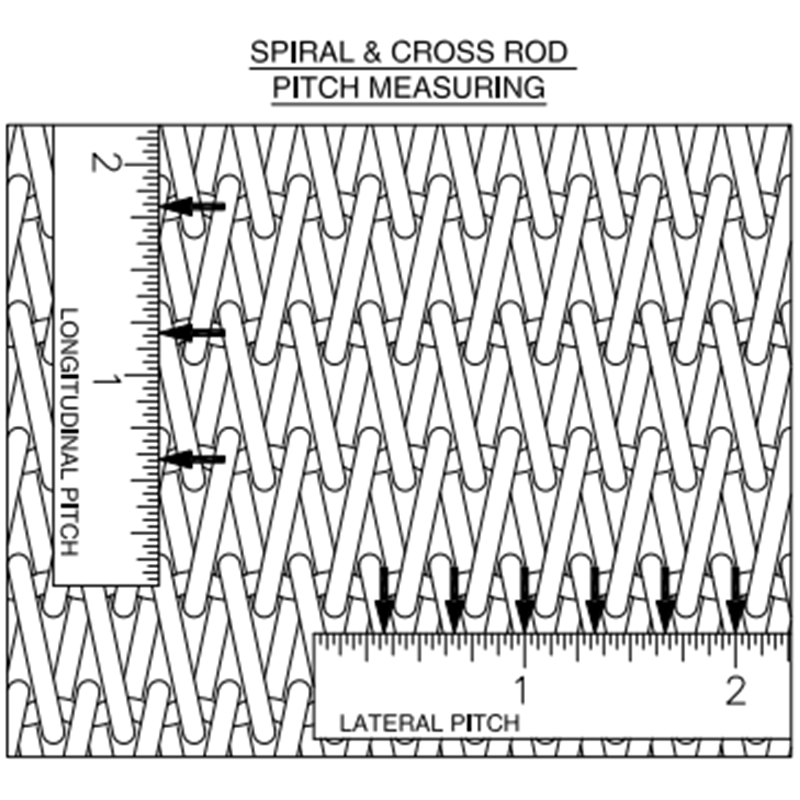

Flat Wire Belting

Cost effective open design belting using flat strip to form spirals in a rectangular opening joined with straight pins. Available in standard duty(3/8” thick) and heavy duty(1/2” thick) series. Available meshes are: standard duyt 1x1, 1/2x1, 1/2x1 modified, 1x1 radius, 1/2x1 radius.

Heavy duty 1x1, 1/2x1, 1/2x1 modified, 1x1radius, 1/2x1radius.

Flat wire belting is available in galvanized, high carbon and stainless steel. A complete line of sprockets, shafts, flights and attachments are available.

BELT SPECIFICATION BELT WIDTH NO.OF OPENINGS BELT LENGTH BELT MATERIAL EDGE FINISH BELT DUTY LATERAL PITCH LONGITUDINAL PITCH OPENING WIDTH

Flat-Flexing Belting

Light weight&open construction makes this belt popular in baking and food processing. Positive driven belting manufactured from stainless steel and music wire. This belt is manufactured in the following standard meshes:

72x.035”, 48x.050”, 32x.082”, 24x.092”,

72x.050”, 42x.050”, 27x.050”, 15x.092”

54x.035”, 42x.062”x 24x.072”

Also available in metric pitch. Complete line of sprockets, blanks, shafts, turn belts and complete conveyor units.

BELT SPECIFICATION BELT NUMBER BELT LENGTH STRANDS/FT WIRE DIAMETER BELT WIDTH #OF SPACES EDGE FINISH MATERIAL Chain Drive Belting

Mesh belting with chain attached to each edge for positive drive. The chain can be attached by rods that pass through the mesh or with channel/bar supports that are bolted/welded to the chain. The construction method used in based on the capacity required and the mesh will be determined by the smallest part size. Most common meshes are balanced weave mesh woven to accommodate the support spacing.

Common applications are ovens, quench tanks, wahers, fryers, greezers and any application that requires posivive drive to eliminate any potential tracking problems.

BELT SPECIFICATION VARIABLES DATA MATERIAL ''A'' ''B'' ''C'' ''D'' ''E'' ''F'' CHAIN NUMBER ROLER SIZE STD or OVR EDGE FINISH WW CT WD MESH SPEC. NOTES: (IE. SIDE PLATES,FLIGHTS,OVERSIZED NODS ETC.) PLEASE CIRCLE CRITICAL DIMENSION ''A'' ''B'' ''C''

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.

Related Products

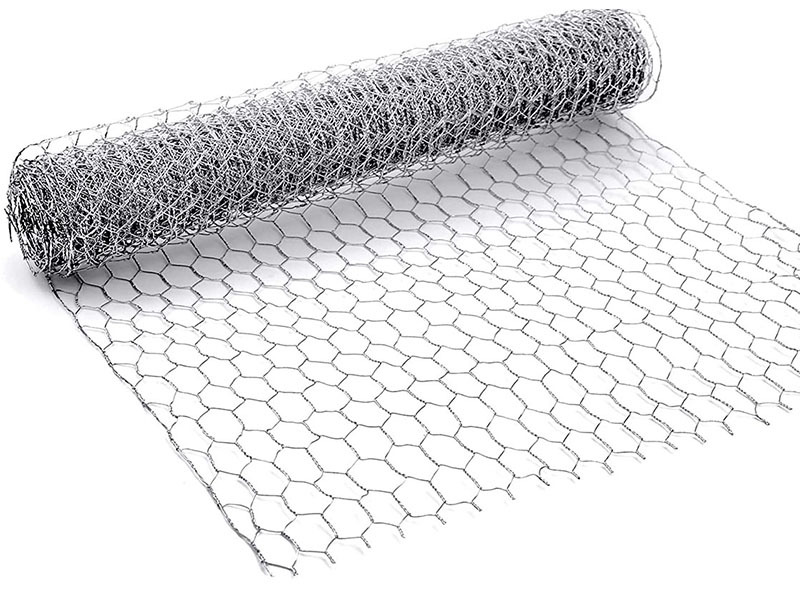

Hexagonal mesh is a net-like material woven or welded from metal wire, named for its hexagonal (honeycomb) mesh structure. It is also known as hexagonal wire mesh, chicken wire, hex mesh, or gabion mesh.

3D Curved Fence is made by welded wire mesh panels with curves and fence post.The series of protective mesh are simple in structure, beautiful in practicality, easy in transportation,convenient in installation and suitable in topography. 3D Curved Fence is pretty light yet durable, The surface treatment of Welded wire mesh fence includes: hot-dipped galvanized, PVC coated, powder coated.

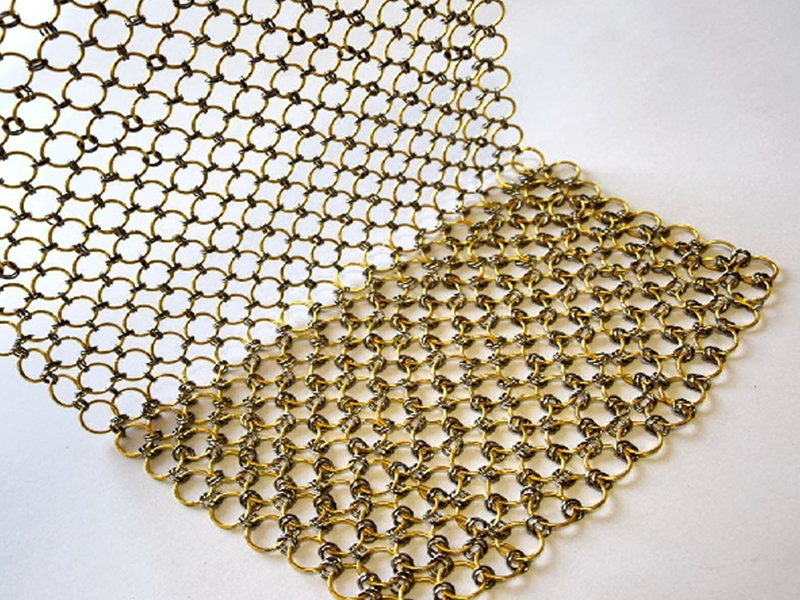

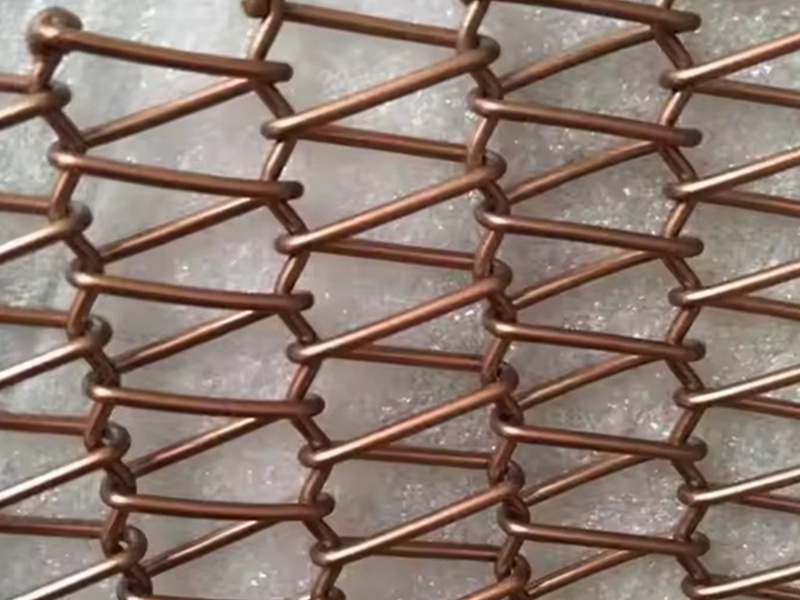

decorative metal curtain is a stylish and functional architectural element made from metal mesh, chain links, or interlocked rings. It is used in both residential and commercial interiors and exteriors for aesthetic appeal and practical purposes.

decorative metal curtain is a stylish and functional architectural element made from metal mesh, chain links, or interlocked rings. It is used in both residential and commercial interiors and exteriors for aesthetic appeal and practical purposes.